Research Center

-

-

Research Center for Surface/Interfacial Micro/Nano-technology

-

Research Center for Additive Manufacturing Technology and Engineering

-

Research Center for Electromagnetic Strengthing for Tools and Bearings

-

Research Center for Intelligent Security Technology and Equipment

-

Research Center for Applied Biological Technology and Equipment

Advanced Automotive Retarder Research Institute

The Advanced Automotive Retarder Institute of Tianjin High-end Equipment Research Institute of Tsinghua University was established on June 20, 2016. It is composed of a team led by Professor Li Desheng, a professor, two associate professors, and a number of doctors and masters.

The construction goal of this institute is to rely on the intellectual resources of well-known domestic universities, grasp the most cutting-edge technology of international retarders, actively expand academic exchanges at home and abroad, carry out in-depth theoretical and experimental research on retarders, and carry out industry-university-research cooperation with enterprises. it is our responsibility to completely solve the backward situation of large truck retarders in China.

Core Technology

- Eddy current brake water cooling technology, new technology products, with complete intellectual property rights;

- High reliability, low cost design;

- Series of products, adapt to different models, can be installed to different parts;

- Automotive retarder ideal replacement products.

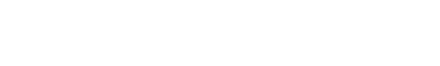

Schematic diagram of double salient structure electro-hydraulic retarder

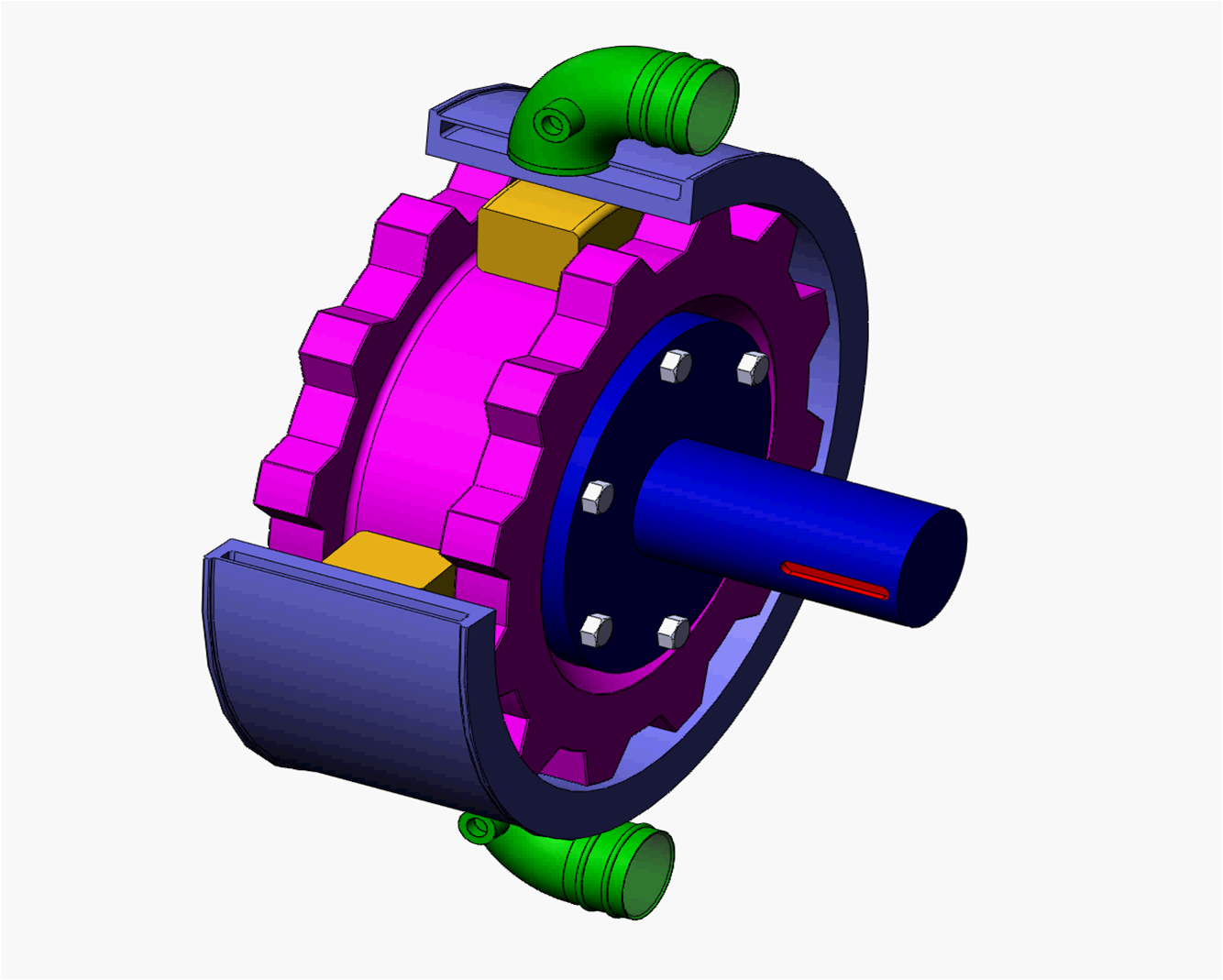

Electromagnetic liquid cooling series retarder concept diagram

The research and industrialization of retarder are as follows:

Research and development and industrialization of hydraulic and electric retarder series products for large trucks;

Engine flywheel integrated retarder research and development;

R & D of energy recovery retarder;

R & D of retarder electronic control box;

Research on military application of retarder.

Automobile retarder is a non-contact braking device, commonly known as the third brake. It has three functions: one is to effectively ensure the safety of large vehicles on mountain roads; the other is to reduce the cost of vehicles; It is to reduce the dust emission and noise of the braking device, energy saving and environmental protection.

At present, there are three main retarder products in the world. In 1936, the world's first eddy current retarder was born in France. In 1961, Voith introduced a hydraulic retarder. In addition, the industry also introduced an engine exhaust brake device. At present, these three retarders occupy the mainstream position. In developed European countries, retarders have been widely promoted in accordance with the law in the 1980 s. Since 2002, China has promoted retarders on certain levels of road transport buses and urban buses. At present, retarders are generally installed on vehicles above 9 meters in accordance with laws and regulations. However, the penetration rate of retarders for domestic heavy trucks is still very low, and many vehicles ease braking difficulties when going downhill by installing large bucket spray hubs to dissipate heat. However, with the promotion of GB-7258-2012, it is expected that in the next few years, the demand for heavy truck retarders will blow out. The demand for retarders is about 1 million units per year, and the market is huge.

From the comparison of the three retarders, the eddy current retarder has 80 years of application history, its structure is relatively simple, the price is low, in the small and medium-sized retarder market has a large proportion, China's bus market is generally installed with this kind of retarder. But its disadvantages are: large volume and weight, large power consumption during work, high temperature, serious thermal recession, and it has not been recognized by the large truck market. The hydraulic retarder has the advantages of small volume and weight, no high temperature when working, and large braking torque, but its technical complexity, high price, poor low-speed characteristics, inconvenient after-sales maintenance and other shortcomings, it is very difficult to promote it in a large area in my country. The engine exhaust brake has low cost, but its braking torque is small at high speed. It is generally used in conjunction with a hydraulic retarder in Europe.

In view of the shortcomings of foreign retarder products and the backward situation of domestic retarder research and development, since the beginning of 2006, the team led by Professor Li Desheng has continuously carried out the research of new retarder. The permanent magnet liquid-cooled retarder developed in the early stage (see Figure 1) fills the international gap. It does not consume electricity when working and has a relatively small weight. However, due to the large price fluctuation and reliability of rare earth magnets, it has not been promoted on a large scale. Based on the research and development of permanent magnet retarder, a double salient structure electro-hydraulic retarder (see fig. 2) was invented and developed in 2011. it avoids the shortcomings of permanent magnet liquid-cooled retarder. compared with traditional eddy current, the working principle is the same, but the basic components are greatly reduced from 36 to 4, the rotor does not generate heat, and the stator is built-in cooling water channel. Due to the use of water cooling, the performance is greatly improved, and the weight and cost are also greatly reduced. Compared with eddy current, it is a subversive technology. Compared with the hydraulic retarder, there is no liquid dynamic seal, the technical difficulty is greatly reduced, the oil medium is not used, the maintenance is free, and the reliability is higher. The invention has been granted a national invention patent and a US patent.

In August 2013, the team transformed scientific and technological achievements based on the invention patent of double salient retarder. After more than two years of efforts, the bus series electro-hydraulic retarder products (see Figure 2) have been underwritten by Qijiang Gear Transmission Co., Ltd., a mainstream domestic bus gearbox manufacturer, and are expected to achieve good social and economic benefits.

|

|

| Fig. 1 Transmission rear-mounted permanent magnet liquid-cooled retarder | Fig.2 Electro-hydraulic retarder with double salient structure |

In the process of developing the tank retarder, the retarder R & D team recently invented an electromagnetic liquid-cooled retarder with an embedded rotor structure (see Figure 3), which is called a liquid-electric retarder. Compared with the double salient structure, this kind of retarder has only three parts. The biggest advantage is that it can greatly reduce the mass and moment of inertia of the rotor, and also overcome the shortcomings of the traditional eddy current retarder. The hydraulic and electric retarder can be used for both military and civilian purposes, and is suitable for both passenger cars and large trucks. It can be installed in the rear shoe of the gearbox, in the middle of the drive shaft, or it can be placed in the flywheel of the engine, which further reduces the weight of the retarder by multiple times!

At present, it has closely cooperated and exchanged with Beiqi Futian, Qingte Group, Changchun FAW, China National Heavy Duty Truck, etc., and has successfully incubated the industrialized company Qingyan Ruineng (Tianjin) Technology Co., Ltd. As a future social demand, the team will further develop energy recovery retarders to meet the needs of further energy conservation and emission reduction in the country and even in the world.

Fig.3 Built-in structure hydraulic-electric retarder

The Institute sincerely accept the recommendations of people from all walks of life, but also willing to carry out various forms of cooperation!

Contact Information

Address: Floor 4, Building 5, Kechuang Huigu Park, East Section of Hongshun Road, Huaming High-tech Zone, Dongli District

Zip Code: 300300

Contact: Miss Li

Fixed telephone: 022-84958260

Mobile Phone: 13693694962

E-mail:13693694962@163.com

Advanced Automotive Retarder Research Institute