Research Center

-

-

Research Center for Surface/Interfacial Micro/Nano-technology

-

Research Center for Additive Manufacturing Technology and Engineering

-

Research Center for Electromagnetic Strengthing for Tools and Bearings

-

Research Center for Intelligent Security Technology and Equipment

-

Research Center for Applied Biological Technology and Equipment

Industrial Automation Equipment and Technology Research Institute

The Institute of Industrial Automation Equipment and Technology is a scientific and technological achievements transformation development and service platform set up by the team of Chen Qiang/Sun Zhenguo from the Department of Mechanical Engineering of Tsinghua University in Tianjin High-end Equipment Research Institute of Tsinghua University. The main research fields are: industrial automation, special robots, non-destructive testing technology And equipment, research and numerical simulation of basic materials for large castings and forgings.

The Institute is composed of associate professor Sun Zhenguo of Tsinghua University as director and Professor Chen Qiang as general consultant. It is composed of in-service professors and associate professors of Tsinghua University, senior experts and chief researchers in domestic metal thermal processing industry, and is composed of researchers, assistant researchers and graduate students. It has undertaken vertical scientific research projects such as the National Natural Science Foundation of China, the national major instrument and equipment development project, and the national high-tech development plan (863), And school enterprise cooperation projects such as Lanshi group.

Industrial Automation Equipment and Technology Research Institute was established.

Since the Institute was officially established in Building 5 of Tianjin High-end Institute of Tsinghua University on August 18, 2016, the aim of the Institute is to deeply study the technology of magnetic adsorption wall climbing robot as the key technical support, take the detection and application of robots as the main promotion direction, take the technology transformation research and product design personnel as the main force of the Institute, take the technology transformation into engineering application products as the goal, and through cooperative research and development projects, quickly launch the relevant climbing robot product series. At the same time, make full use of hot processing technology and industry advantages such as casting, forging and welding, through intelligent and automated means, combined with Tsinghua University's brand, technology research and development, resource advantages, and related production, testing, testing, equipment manufacturing, material manufacturing, and scientific research Supported by the shared and win-win strategic collaboration relationship established by enterprises and units in the industry, actively provide equipment transformation and scientific research and technical services for the production automation of industrial enterprises.

Relying on the resources and strong technology development capabilities of Tsinghua University, relying on the transformation platform of Tsinghua University Tianjin High-end Equipment Research Institute, based on the concept of serving Tianjin and radiating the whole country, the Institute of Industrial Automation Equipment and Technology takes special industrial robots, industrial production automation and The product engineering application in the fields of new materials is the transformation and development goal, and strives to make a major breakthrough in the industrialization of scientific and technological achievements as soon as possible, contribute to the implementation of the "Made in China 2025" strategy.

Introduction to core team members

Associate Professor Sun Zhenguo Director of Research Institute

Secretary General of Welding Society of China Construction Machinery Society

| Resume | Research areas |

Doctor of Tsinghua University Associate Professor, Doctoral Supervisor, Department of Mechanical Engineering, Tsinghua University Member of Professional Committee of Fusion Welding Technology and Equipment | Welding process and equipment Robot Technology and Automation Equipment NDT Technology and Application System | |

Professor Chen Qiang and Mr. Sun Zhenguo's team have successively undertaken more than 10 vertical projects such as the National Natural Science Foundation of China, the National High-tech Development Plan (863), and the National Major Instrument Development Project, and more than 30 horizontal cooperation projects for school-enterprise cooperation. A series of innovative results have been achieved in the fields of welding process equipment, non-destructive testing and evaluation. At present, it has authorized more than 60 Chinese invention patents, published more than 200 academic papers, won 1 second prize for scientific and technological progress in Beijing, 1 second prize for scientific and technological progress in China Petrochemical Association, and 1 first prize for higher teaching achievements in Beijing. | ||

Professor Chen Qiang, Senior Advisor of the Institute

Chairman of Welding Society of China Construction Machinery Society

| Resume | Research areas |

Doctor of Tsinghua University Professor, Department of Mechanical Engineering, Tsinghua University Vice President of Zhejiang Tsinghua Yangtze River Delta Research Institute Vice President of the International Institute of Welding (IIW) Senior Member of China Mechanical Engineering Society | Robot Technology and Engineering Application Intelligent Control of Welding Process and Equipment Automation Multi-information sensing and fusion processing Plasma and Laser Precision Machining Technology Computer Vision and Image Processing | |

Professor Chen Qiang presided over and participated in more than 30 projects, including the National Natural Science Foundation of China, the National 863 High-tech Research Program, the National 973 basic Research Program, the Special funding Program of the Ministry of Education, the National Science and Technology Research Program, the National West-East Gas Transmission Project, as well as enterprise-oriented technology development projects and international cooperative research projects. It has obtained 27 national invention patents, published 2 monographs and published more than 200 papers, of which SCI/EI/ISTP includes more than 100 articles. | ||

Associate Professor Shi Wei Technical Director of Research Institute

Director of Heat Treatment Branch of China Mechanical Engineering Society

| Resume | Research areas |

Doctor of Tsinghua University Committee Member of Heat Treatment Committee of Beijing Mechanical Engineering Society | Microstructure and residual stress control of metal material forming process Multi-physics coupling modeling and numerical simulation of heat treatment process: process design and numerical simulation of ingot casting, forging and heat treatment process of large forgings Simulation analysis technology of manufacturing system: simulation analysis and optimization of design scheme of automatic industrial material conveying system | |

| Mr. Shi Wei presided over the national natural science foundation joint fund project "research on constitutive behavior and numerical simulation of quenching and tempering process of low alloy ultra-high strength steel" and the national international science and technology cooperation special project "cooperative research on heat treatment stress and distortion control of high value-added mechanical products". Participate in the research work of "973" project "basic science problems of mechanical equipment remanufacturing" sub-project "surface/interface behavior and mechanism of remanufactured parts. Participated in the completion of 1 project of the State Planning Commission, 2 projects of the National Science and Technology Support Plan of the Eleventh Five-Year Plan, and a number of projects of the National Natural Science Foundation. Cooperate with China First Heavy Machinery Group Corporation, Maanshan Iron and Steel Co., Ltd. Heavy Machinery Company and other enterprises, and presided over the completion of a number of corporate cooperative scientific research projects. It provides system simulation consultation on the design and implementation of material conveying system for Swisslog of material conveying equipment and system integration manufacturers. The simulation consultation project involves many well-known enterprises, including Uni-President, Jingdong, Ningbo Cigarette Factory and TI Singapore Factory. He has published more than 40 academic papers, including 4 in SCI and 9 in EI. | ||

core patent technology

■A Magnetic Adsorption Wall-Climbing Robot with Surface Adaptive Ability

■A non-contact magnetic adsorption wheeled wall-climbing robot

■Multi-body magnetic adsorption adaptive wall-climbing robot

■Gap magnetic surface topography detection robot and surface topography measurement method

■The gyro drift estimation compensation method and device based on the rotation of the inertial measurement unit.

■Axle radial ultrasonic automatic flaw detection device and control method

■Automatic radial ultrasonic flaw detection method for shaft parts

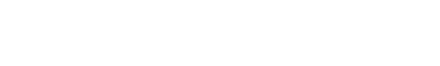

Research on Robot Repair Welding Operation Unit for Large Structural Parts with Complex Curved Surface such as Large Hydropower Station

Introduction to the results of the Institute

Development of special robots for forming and manufacturing-special robots for repair operations of large structural parts with complex curved surfaces;

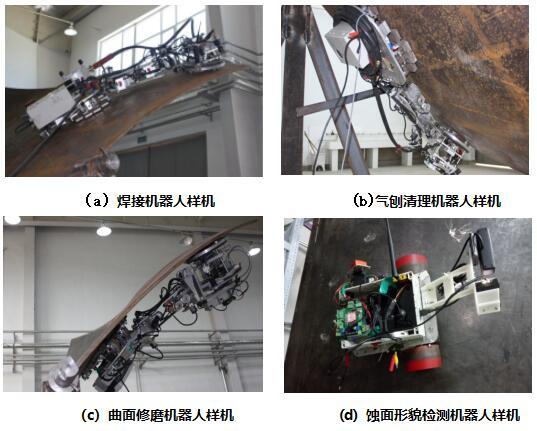

Laser light source lighting technology and product development-marine and underwater laser light source long-distance lighting products;

Intelligent welding process and equipment research and development-welding process visual sensing, seam tracking and automatic control;

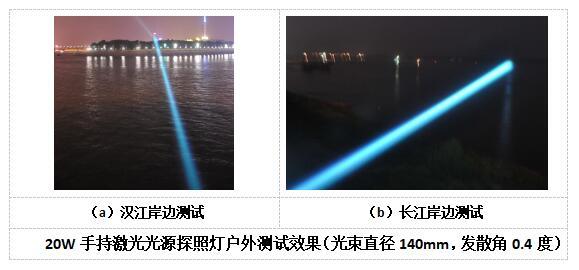

Research and numerical simulation of basic materials for large castings and forgings for high-end equipment-Research on key manufacturing technologies for large castings and forgings for million-kilowatt nuclear power equipment;

Research on intelligent manufacturing and workshop automation equipment -- hydraulic and electrical system of multi-directional die forging press, workshop automation transformation of heavy equipment, visual navigation AGV robot, intelligent warehouse logistics modeling simulation and automation equipment;

Non-destructive testing technology and equipment-locomotive axle digital ultrasonic flaw detection equipment, spherical tank TOFD flaw detection robot;

Numerical Calculation of Quenching Stress of 300MW Steam Turbine Low Pressure Rotor (Material 26Cr2Ni4MoV Steel)

Contact Information

Address: Building 5, Kechuang Huigu Park, East Section of Hongshun Road, Huaming High-tech Zone, Dongli District

Zip Code: 300300

Contact: Zou Wei

Fixed telephone: 022-84959181

Mobile Phone: 18622987010

E-mail:zouw@tsinghua-tj.org

Fax: 022-84959181

Institute