Research Center

-

-

Research Center for Surface/Interfacial Micro/Nano-technology

-

Research Center for Additive Manufacturing Technology and Engineering

-

Research Center for Electromagnetic Strengthing for Tools and Bearings

-

Research Center for Intelligent Security Technology and Equipment

-

Research Center for Applied Biological Technology and Equipment

Heavy Equipment Technology Research Institute

The Heavy Equipment Technology Research Institute originated from the forging group of Tsinghua University. It has independent and original core technologies such as steel wire prestress winding, prestress splitting and closing, and ultra-high pressure technology. It is engaged in the development and service of heavy hydraulic presses, ultra-high pressure systems, forging processes, special tooling molds and other products for aerospace, weapons, petroleum and petrochemical, transportation, special industries and other fields. The team has undertaken and completed the research and development tasks of major national equipment for many times. The research results include 400MN aviation precision die forging hydraulic press, 300MN isothermal forging hydraulic press, 600MN heavy die forging hydraulic press, 360MN ferrous metal extrusion unit, etc., providing strong support for the national heavy equipment to stand in the forest of the world.

Core Technology

■%Winding Technology of Prestressed Steel Wire

■%Pre-stress split-up technology

■ High pressure/ultra high pressure technology

■ Full set of forging production line process solutions

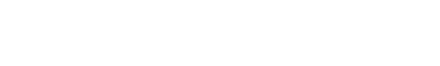

Simulation of Multi-directional Die Forging Process

industrialization process

The team has decades of scientific research and engineering accumulation in the field of heavy equipment and heavy hydraulic press design. The typical projects undertaken by the team in recent years are as follows:

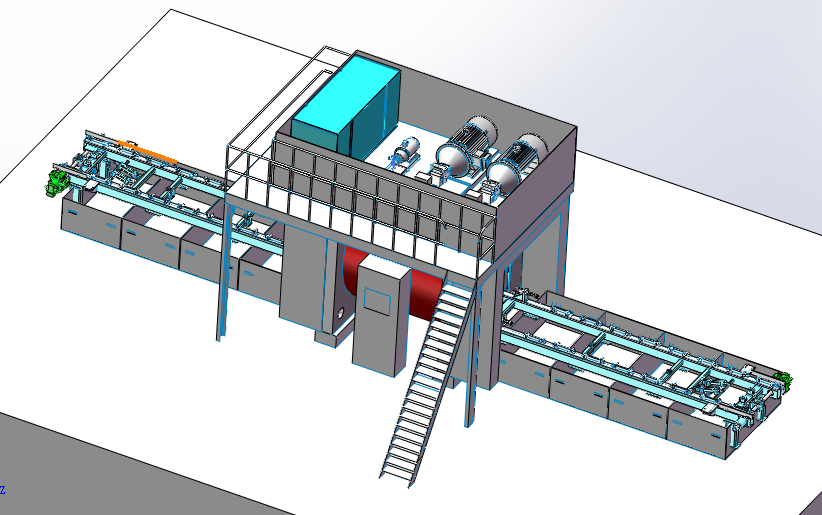

Steel wire prestressed winding die forging hydraulic press: self-developed 100MN-1600MN series high-rigidity heavy-duty die forging hydraulic press, which is mainly used for precision die forging of titanium alloy, high-temperature alloy, powder alloy, high-strength steel, aluminum alloy and other materials. It has die forging, isothermal die forging, hot die forging and constant strain rate control modes, it has the advantages of high stiffness (better than 1/8000), high balance accuracy (better than 0.2 mm/m), high fatigue life and short construction period.

400MN die forging hydraulic press 300MN die forging hydraulic press

Steel wire prestressed winding extruder: can independently develop 100MN-1000MN extruder. The 360MN black metal vertical extrusion press unit adopts ultra-high pressure and steel wire prestressed winding technology. The project was put into operation in 2009. After the project was put into operation, it broke the long-term monopoly of foreign countries and was rated as one of the top ten landmark projects in the new era of my country. The project won the second prize of National Science and Technology Progress Award.

Steel wire prestressed winding plate forming hydraulic press: self-developed 50MN-600MN plate forming hydraulic press, using ultra-high pressure (working pressure 100MPa) and steel wire prestressed winding technology, has a number of patented technologies, marking China's plate forming pressing technology level has made new achievements.

400MN plate forming hydraulic press

Steel wire prestressed winding multi-directional die forging hydraulic press: the use of "steel wire winding prestressed orthogonal preload frame" technology, effectively solve the orthogonal load, the force frame in the structure and mechanics of mutual interference contradiction, improve the fatigue strength and stiffness of the frame. Through the balance and guiding design of vertical moving beam, the design and manufacture of large horizontal side frame, the balance control of bidirectional perforation of horizontal oil cylinder, multi-directional die forging technology and many other core technologies, the 40MN-1600MN series new structure multi-directional die forging hydraulic press can be independently developed.

40MN/64MN multi-directional die forging hydraulic press

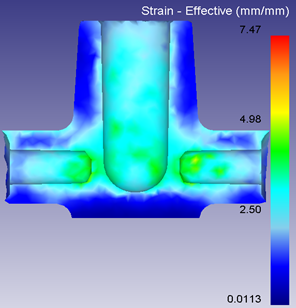

Steel wire prestressed winding aluminum wheel forging hydraulic press: Aluminum alloy wheel forging is a typical small table top concentrated load, single master cylinder works, steel wire prestressed winding technology is the perfect solution: prestressed winding machine frame prestressed winding hydraulic cylinder (68MPa). The use of steel wire prestressed winding ultra-high pressure master cylinder makes the forging projection area basically the same as the forging, so it has the following advantages: high stiffness design, high reliability operating life, customized design, etc. 120MN, 80MN, 50MN production lines have been developed.

Forging aluminum alloy wheel hydraulic press production line

Rubber bag forming machine/liquid filling forming machine: it can be used for bulging, cavity forming, block forming and deep drawing forming of aluminum alloy, stainless steel, high temperature alloy and other materials, such as fairing, frame plate, rib, bracket, etc., and can also be used for punching and grouping blanking of thin plate parts.

Free forging hydraulic press: can independently develop 25MN-250MN free forging hydraulic press/fast forging hydraulic press. It is equipped with a quick anvil changing device and a horizontal anvil shifting device. The structure is rigid and stable. Hydraulic control system to pump direct transmission as the main valve control as a supplement. The equipment has compact structure and small footprint, which meets the requirements of national intelligent manufacturing standards and industrial 4.0.

Contact Information

Address: Building 4, Kechuang Huigu Garden, East Section of Huaming Hongshun Road, Dongli District

Zip Code: 300300

Contact: Liu Yongqian

Fixed telephone:022-84819452

Mobile phone:18618269646

E-mail:liuyq@tsinghua-tj.org

Fax: 022-84819452

Heavy Equipment Technology Research Institute