Research Center

-

-

Research Center for Surface/Interfacial Micro/Nano-technology

-

Research Center for Additive Manufacturing Technology and Engineering

-

Research Center for Electromagnetic Strengthing for Tools and Bearings

-

Research Center for Intelligent Security Technology and Equipment

-

Research Center for Applied Biological Technology and Equipment

Robotics and Automation Equipment Engineering Research Institute

The Institute of Robotics and Automation equipment Engineering of Tianjin High-end equipment Research Institute of Tsinghua University (hereinafter referred to as "Robotics") was formally established on February 1, 2015. It is the intelligent robot and automation equipment achievement and technology transformation and industrial incubation base of Professor Chen Ken of Tsinghua University in Tianjin High-end Institute. The team led by Professor Chen Ken is composed of two major parts: the Research Office of Tsinghua University and the Engineering Research Institute of the High-end Institute. It has long been engaged in the research and development of intelligent robots and automation equipment, and is at the leading domestic level in the research and development of aviation special robots and automated manufacturing equipment. Guided by the market demand of intelligent robot technology and automation equipment of the country and society, the team carries out the transformation of research results, the development of engineering technology and the promotion of industrialization, so as to promote the integrated development of production, teaching and research of advanced robots and automation equipment in China. The Institute of Robotics currently has 20 core backbone employees, including 2 professors and researchers, 2 senior engineers, and more than 13 assistant researchers and engineers. Three of them have a doctorate in engineering, and most of the team members have a master's degree. On the platform of Tianjin High-end equipment Research Institute of Tsinghua University, the Institute of Robotics has become an innovative intelligent robot and automation equipment technology engineering center integrating development, design, production and sales. At present, Qingyan Huayu Intelligent Robot Tianjin Co., Ltd., Qingyan Tongchuang Robot (Tianjin) Co., Ltd. and Qingyan Huayi (Tianjin) Education Technology Co., Ltd. have been hatched, entering some key subdivisions with advantages.

The Institute's main areas of strength include:

■ Special field custom robot spraying system

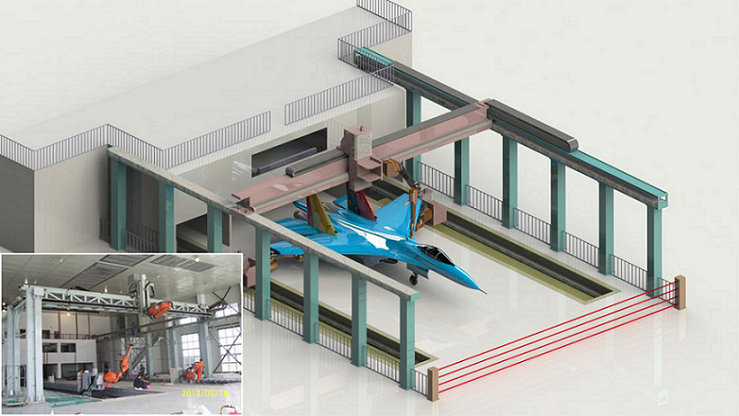

Inlet Spraying System

Ultra-long 14-degree-of-freedom multi-redundant robot, long cantilever vibration suppression technology, redundant coordination control, complex closed space surface trajectory and obstacle avoidance planning.

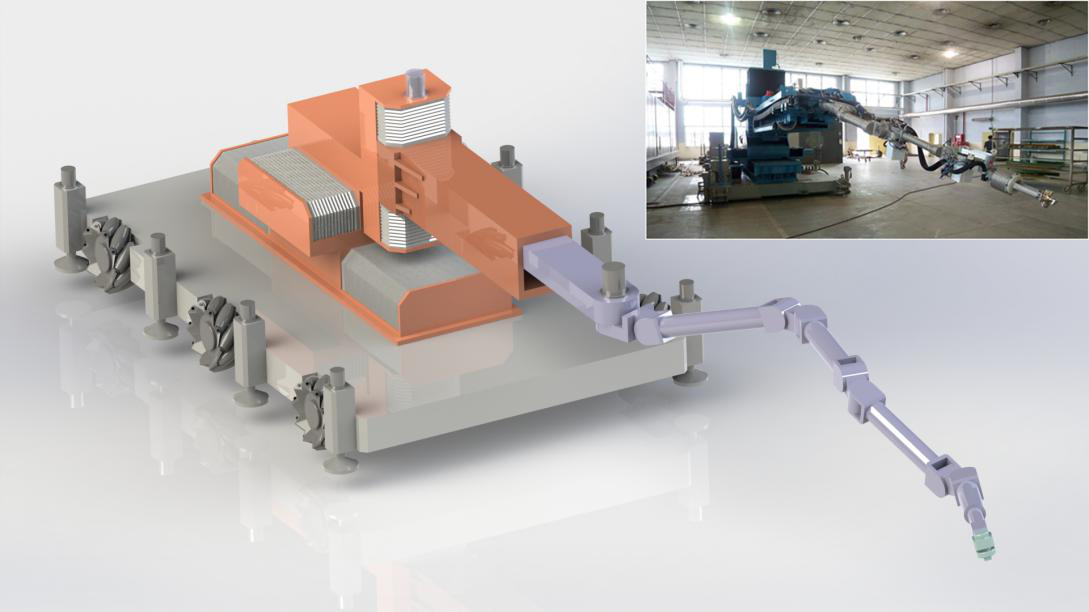

Whole machine spraying project

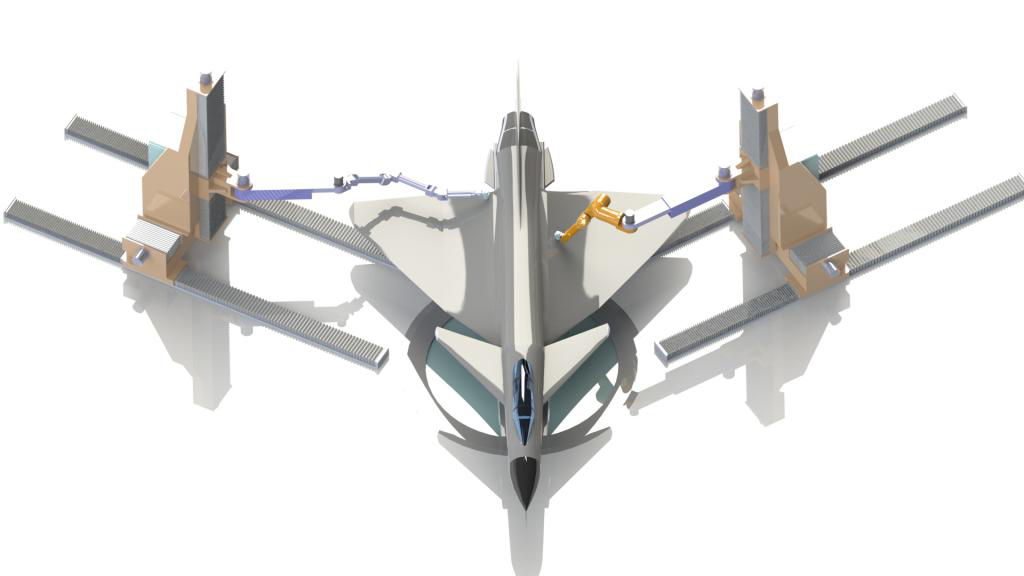

Large 9 degrees of freedom multi-robot, complex spraying surface division and station optimization, complex knot surface planning, multi-robot coordination control, special spraying process, real-time variable speed spraying control.

The self-developed six-axis, seven-axis joint arm as the core of the whole spraying system. The attitude adjustment of the aircraft is realized by the turntable, and the two multi-degree-of-freedom mechanical arms work together to complete the spraying of the outer surface of the aircraft and the inner surface of the inlet at the same time.

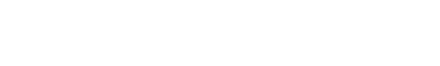

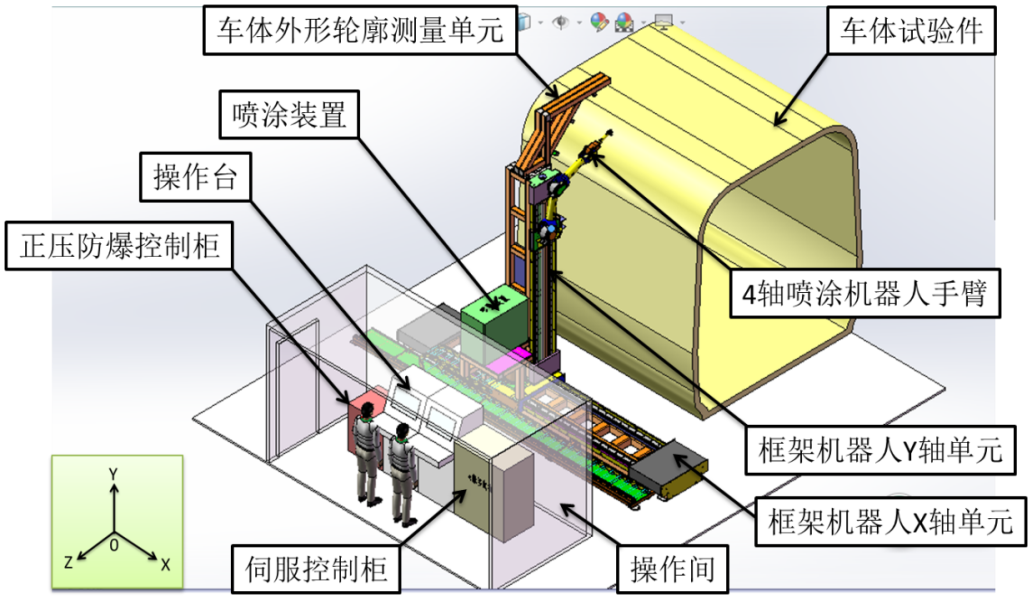

High-speed rail spray putty project

The robot automatic putty spraying experiment platform based on machine vision is composed of ground rail platform, machine vision system, putty spraying system and control system. It can realize the three-dimensional reconstruction of the surface of the rail vehicle and detect the defects such as the surface depression.

Military equipment spraying and polishing production line

The main automatic spraying of the outer surface of the product is a production line scheme integrating masking cleaning, paint surface polishing, bottom/finish coating and logo spraying, drying, curing, dismantling and masking. The production line consists of a robot grinding system, an automatic spraying system, a skid chain system, an electrical system and a central control system.

Seven-axis, six-axis spraying robot products

The modular design can be freely assembled into a long arm structure with multiple degrees of freedom according to work needs; the motor, sensor and cable are all located inside the structure; the radial size is small, suitable for operation in a narrow space. Have a complete independent research and development control system.

■ Development and customization of automated assembly systems and technical services

Wing-to-Body Assembly System

Based on the shaft hole force position mixed flexible assembly control, the automatic precision of the shaft hole of the large parts of the aircraft is realized, and the whole process of automatic assembly based on laser tracker guidance.

Vertical Tail Fitting Assembly System

Based on image recognition and online real-time feedback, the automatic precision of multi-hole position of large parts of aircraft is realized, and the whole process of automatic assembly based on the segmented guidance of "robot laser tracker image recognition" is realized.

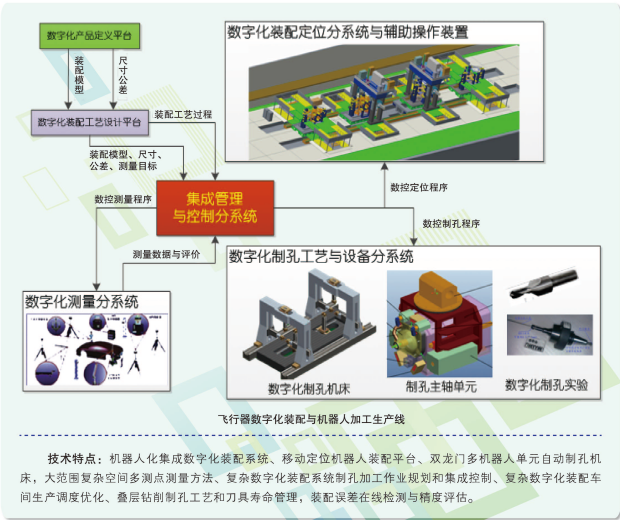

Aircraft fuselage digital assembly project

The system consists of many subsystems, such as robotization, digital integrated assembly system, mobile positioning robot assembly platform, double gantry multi-robot unit automatic hole making machine tool and so on. A large-scale complex space multi-point measurement method with independent property rights has been applied. Complex digital assembly system hole making and processing operation strategy; Control integration, complex digital assembly workshop production scheduling optimization management concept; Research results of laminated drilling hole making process; Tool life management, assembly error online detection and precision evaluation and other quality evaluation systems and many other advanced achievements.

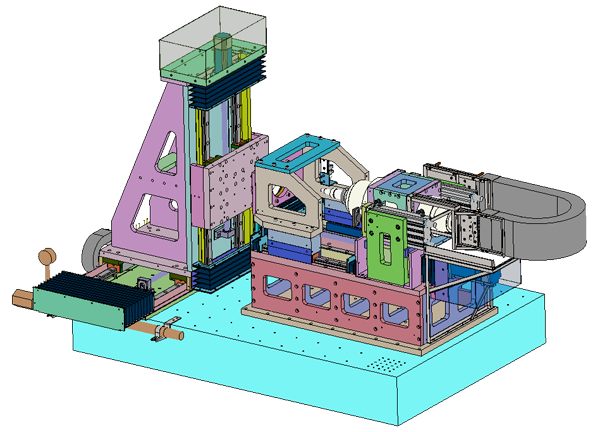

Automatic drilling head system

Automatically complete the compaction and drilling of the test workpiece, and can realize the control of compaction force, cutting amount and countersink depth, and integrate auxiliary functions such as micro-lubrication, tool condition monitoring, dust collection and chip collection, and video recording. It can be used to study the drilling mechanism and process optimization of composite/titanium alloy, composite/aluminum alloy and other laminated materials.

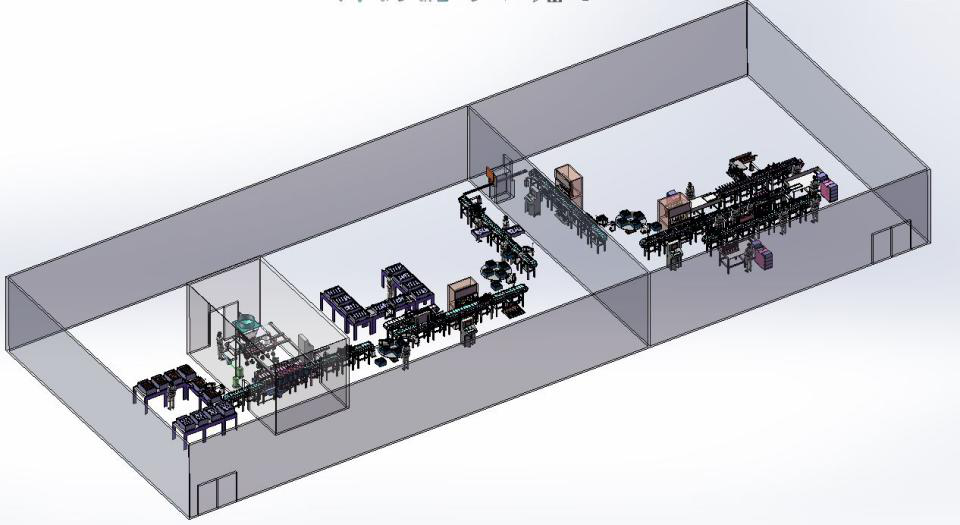

Military assembly line

The whole assembly line is composed of four subsystems, namely, automatic weighing and releasing FSY system, automatic tightening system, YX automatic tightening system and transmission system, which are connected in series successively, and each two adjacent subsystems are connected through a transfer platform.

Landing Gear Assembly and Inspection System

It is an integrated landing gear assembly and testing platform. The multi-module combined structure is adopted, which can realize the automatic assembly and quality inspection of the landing gear, and has the ability of integrated management and analysis of assembly and quality inspection data.

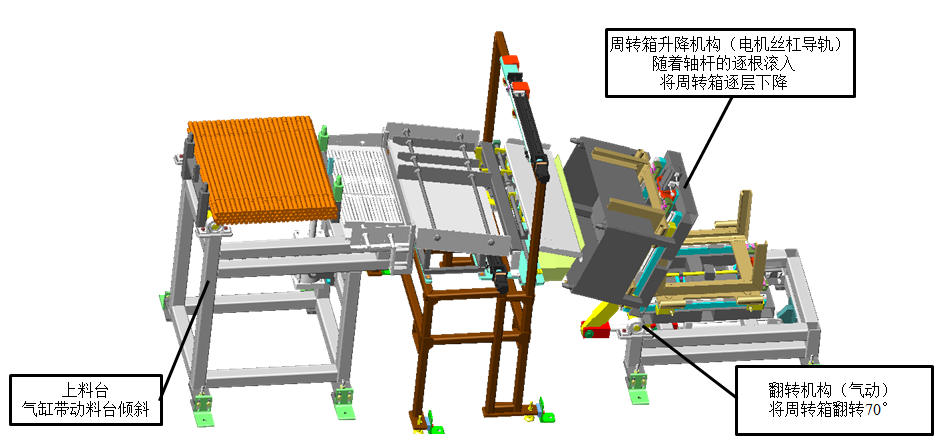

Lathe automatic loading and unloading project

This project has multiple subsystems. Including lathe automatic loading and unloading system, punching machine automatic loading and unloading system, rolling wire automatic loading and unloading system, shaft automatic detection system and other 4 sets of sub-systems.

■ Special field of composite materials processing and technical services

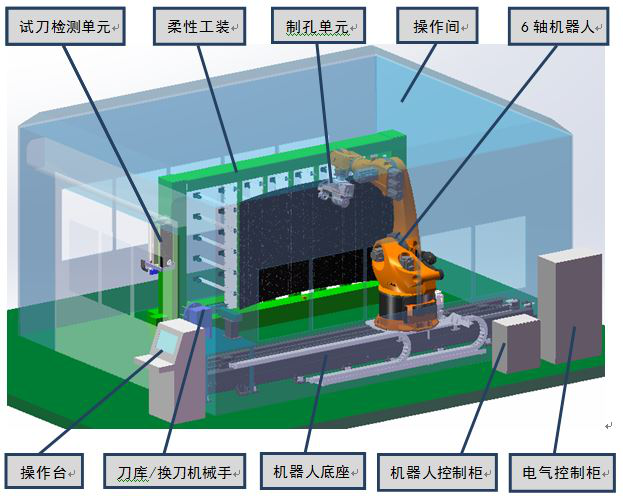

Compound material trimming system of an aircraft R & D center

This set of technical solutions includes two subsystems, namely, a robot cutting and hole-making system and a composite flexible tooling system. Among them, the robot cutting and hole-making system is used to realize the cutting and hole-making functions of curved carbon fiber composite wall plate parts, and the composite flexible tooling system is used to realize the clamping and positioning function adapted to different sizes and curvature wall plates.

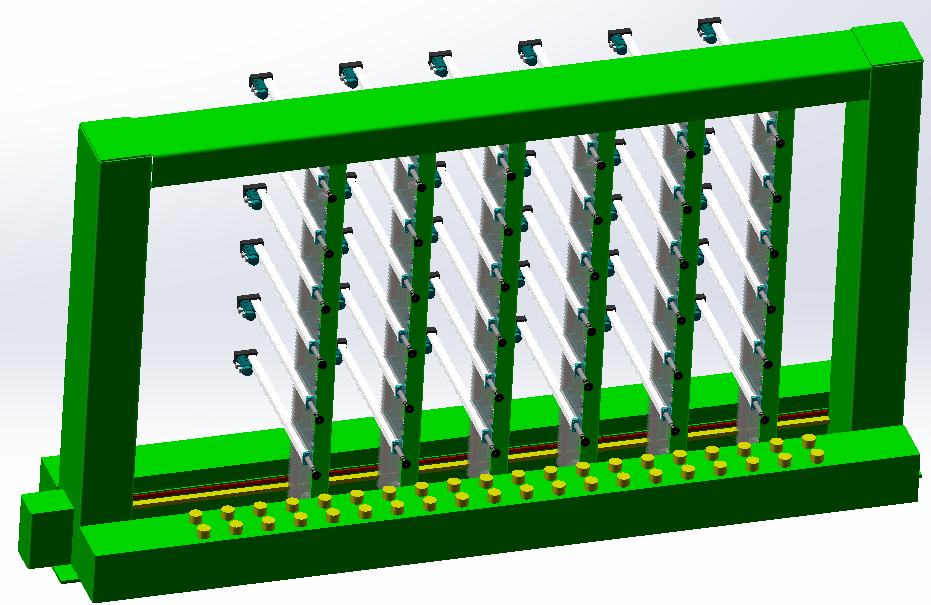

Composite flexible support equipment

This set of flexible tooling optional integrated drive servo motor, the use of group series bus control mode, compared to the traditional split motor, this configuration scheme can greatly simplify the system cable and its topology, but also contribute to the system TMC electromagnetic compatibility performance improvement, the stability of the operation and control equipment will also be improved.

Industrialization process:

The Robot Institute has developed new product prototypes such as modular multi-degree-of-freedom long-arm spraying manipulator, education platform based on biped walking robot, intelligent service robot and 3C cooperative robot. Guided by the national and social market demand for intelligent robot technology and automation equipment, the Institute has carried out research achievement transformation, engineering technology development and industrialization promotion, and promoted the integrated development of production, education and research of advanced robots and automation equipment in China, at present, Qingyan Huayu Intelligent Robot Tianjin Co., Ltd. and Qingyan Tongchuang Robot (Tianjin) Co., Ltd. have been hatched. The Robot Institute will eventually become an innovative intelligent robot and automation equipment technology engineering research and development center integrating development, design, production and sales.

As one of the basic equipment of my country's high-end equipment manufacturing, robots are an important part of the strategic emerging industries of high-end manufacturing equipment in my country's "13th Five-Year" development plan. A major opportunity to accelerate the development process of China's robot technology and industry with intelligent robots as the main body is an objective requirement for China to establish a strategic emerging industry in the new era. We look forward to working with you to make our due contribution to the development of intelligent robots and automation equipment technology and the development of strategic emerging industries in China.

Contact Information

Address: Building 4, Kechuang Huigu Park, East Hongshun Road, Huaming High-tech Zone, Dongli District

Zip Code: 300300

Contact: Rampo

Fixed telephone: 022-84819418

Mobile Phone: 18522169653

E-mail:lanbo@tsinghua-tj.org

Fax: 022-84819410

Robotics and Automation Equipment Engineering Research Institute