Research Center

-

-

Research Center for Surface/Interfacial Micro/Nano-technology

-

Research Center for Additive Manufacturing Technology and Engineering

-

Research Center for Electromagnetic Strengthing for Tools and Bearings

-

Research Center for Intelligent Security Technology and Equipment

-

Research Center for Applied Biological Technology and Equipment

Research Institute of Composite Manufacturing and Intelligent Identification

Introduction to 1. Research Institute

The Institute of Composite Manufacturing and Intelligent Identification is a scientific research institution under the Tianjin High-end Equipment Research Institute of Tsinghua University. It takes non-standard automation, surface engineering, visual intelligent identification, unmanned equipment and electric drive, digital algorithms and applications as its main technical directions. Based on high-end equipment and advanced manufacturing industries, it develops robots, non-standard equipment, digital twins, intelligent quality inspection and other products.

Liu Dameng, director of the Institute and a young Yangtze River scholar, has won two provincial and ministerial awards and is engaged in the manufacture, testing and intelligence of high-end equipment. The team has a total of 38 R & D personnel and has rich development and delivery experience in non-standard automated production, rubber machinery, special spraying, laser polishing, intelligent robots, digitization and other fields.

2. core technology

(1) Non-standard automation engineering technology

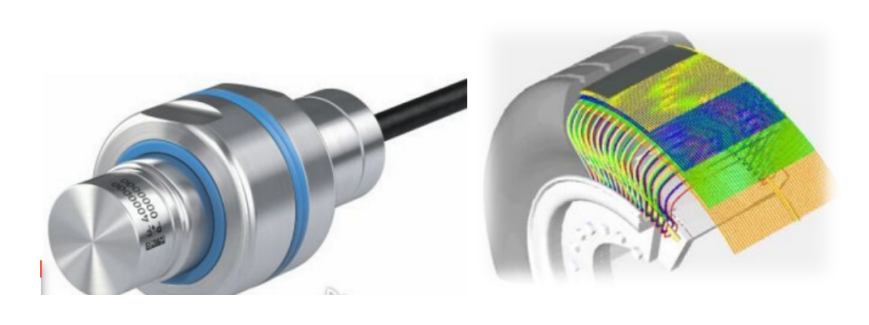

(2) rubber-metal interface control technology

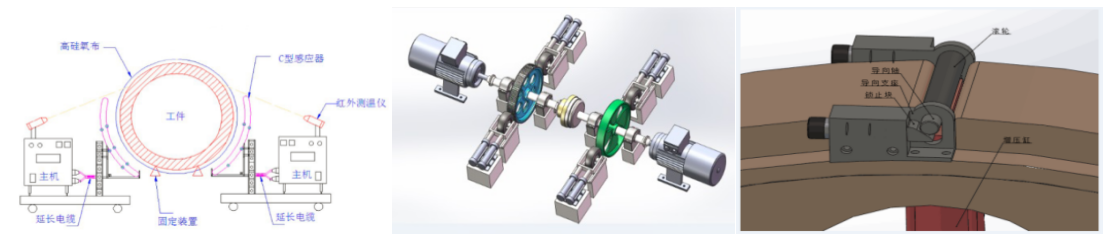

(3) Complex winding technology of strip rubber fabric

(4) Special testing technology for rubber wear

(5) High-precision visual guidance and sensing technology

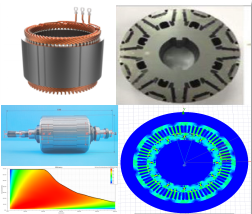

(6) High power density electric drive technology

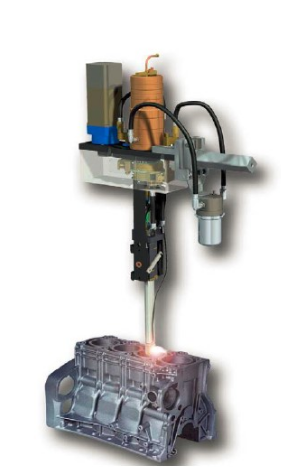

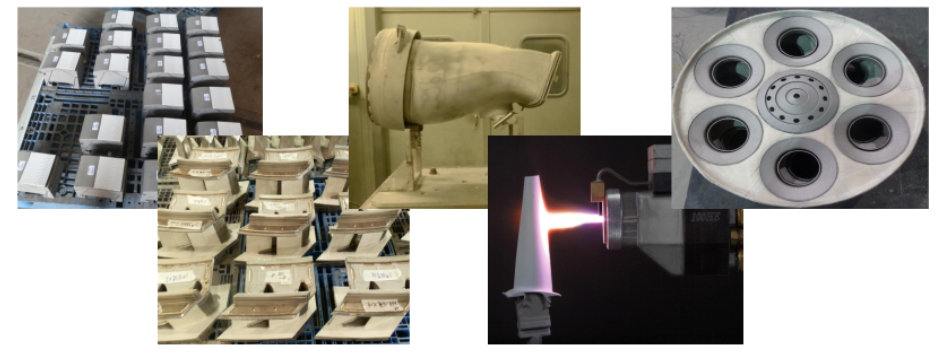

(7) Supersonic spraying technology for complex structures

(8) confined space plasma spraying technology

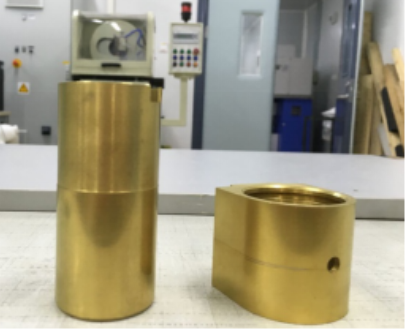

(9) Special alloy coating manufacturing technology

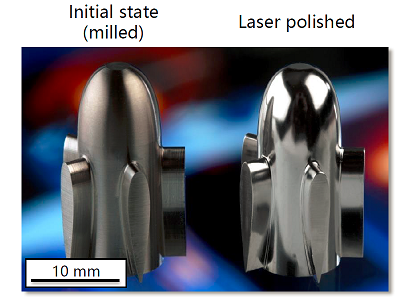

(10) Laser polishing, high-speed cladding technology

(11) Laser cleaning technology

(12) Digitalization and Algorithm Application Technology

3. industrialization process

(1) Special testing equipment

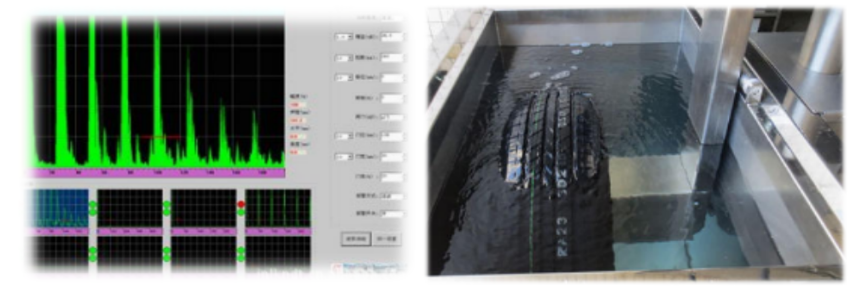

Aviation and aerospace high-speed radial tire dynamic wheel roller test bench

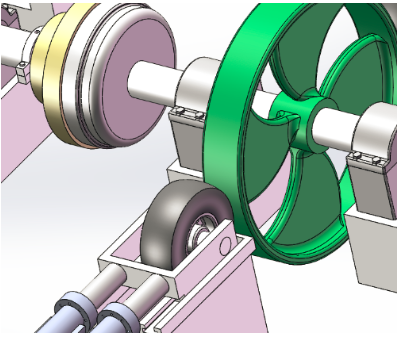

Non-destructive Testing of Tire Cord

(2) Mechanics, spectroscopy real-time in situ composite detection technology, tire life, defects and wear detection and prediction.

(3) Special-shaped parts spraying, high temperature resistance, corrosion and wear composite coating coating equipment

(4) Customized surface coating technology research, raw material development.

Insulating coating technology: spraying insulating coating on the surface of a specific substrate to effectively increase the resistance of the workpiece, prevent the current from passing through and corrode the workpiece, and apply it to various parts of the ship such as insulating bearings, Haitong valves and cabin fittings.

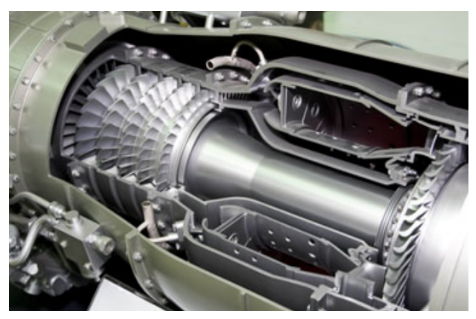

Wear-resistant coating technology: It is a major application of thermal spraying. Whether it is flame, spray welding, plasma, or supersonic spraying, it can be made into wear-resistant coatings with their own characteristics. It has good wear resistance and is widely used in aviation. Engine core parts, gas turbine parts, automotive engine parts, mining machinery, marine equipment and other aerospace, energy, automotive and other industries.

Thermal barrier coating technology: it is physically combined with the surface of high temperature resistant metal or super alloy substrate material by thermal spraying, which plays the role of heat insulation and reducing the temperature of the substrate, and is applied to aviation, aerospace and civil hot end components such as gas turbine blades and aircraft engine blades.

Sealing coating technology: coating in the gap part of the aircraft engine airflow channel, is the aviation, aerospace industry in the rapid development of high temperature sealing, gap technology, is one of the important applications of modern thermal spray coating.

(5) Laser surface rounding technology has successfully replaced the peelable cloth method and gear ring sandblasting process of composite materials, providing a green environmental protection solution for the composite materials and gear industry.

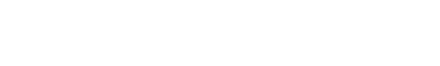

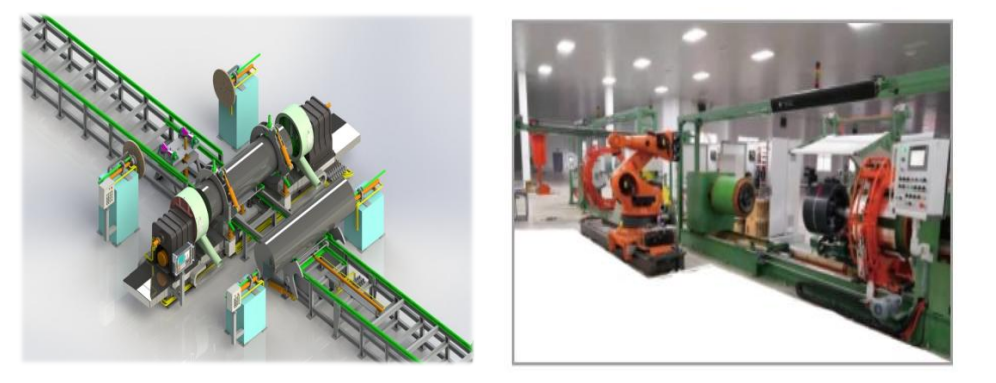

(6) The first-generation aviation radial tire building machine developed has been officially installed as an aviation tire manufacturer. It is a special equipment for the development of high-performance radial aviation tires for my country's new generation of aircraft. The project won the first prize of Tianjin high-end equipment in 2021 and the national high-end equipment finalist award.

(7) Research on key components and software technologies of the new generation of intelligent AGV(IGV) to realize the "five new concepts" of AGV-acceleration, overtaking, obstacle avoidance, waiting and grouping. Improve production line flexibility and increase production capacity.

4. project case

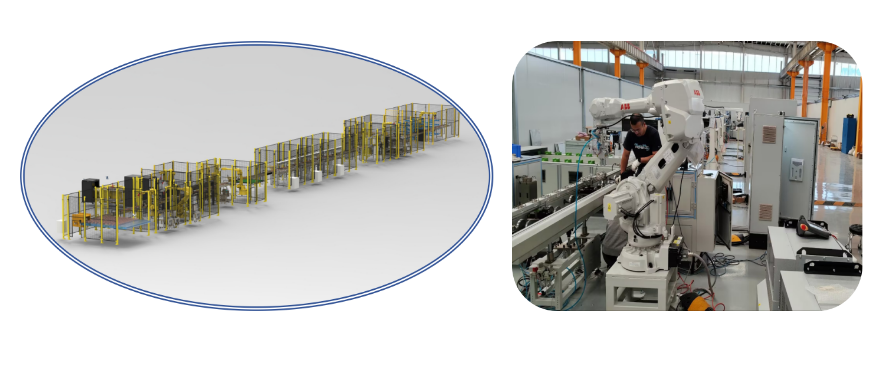

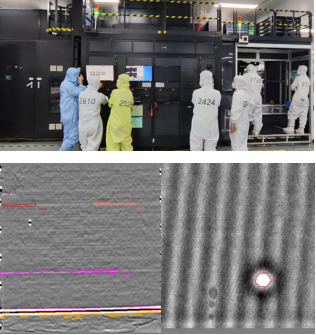

(1) Undertake the design and development of a tire manufacturing company's aviation radial tire molding machine, gel coat testing, cord offset testing, and research and development of shearing and piercing equipment.

(2) Undertake a nuclear energy machinery company JLG component assembly automation device project, the production line is based on automation technology and vision technology and intelligent software management technology as one of the unmanned intelligent production line, in the domestic unmanned workshop, the construction of the black light factory has reference significance.

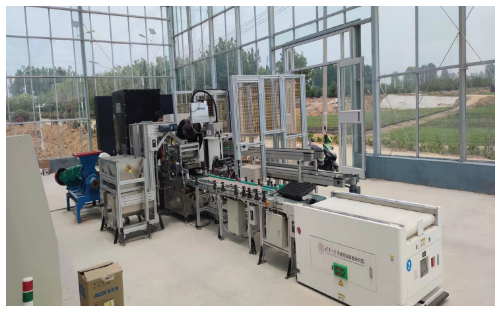

(3) Developed the domestic first blueberry automatic planting machine instead of artificial planting technology, which played a role in promoting industrial upgrading in the blueberry planting industry.

(4) Undertake the research and development of internal thread detection technology of an automobile company, which can measure large diameter, middle diameter, small diameter, pitch, thread depth and thread surface defect detection.

(5) Undertake the research and development of visual inspection technology for LCD defects of an optoelectronic company, which breaks the disadvantages of traditional manual quality inspection of LCD screens, improves the stability of products, and saves costs for enterprises.

(6) Undertake the research of intelligent cluster system-level breakthrough technology of an automobile company, the research of high reliability and refinement technology of steering wheel, and the research of AGV repeated positioning accuracy technology.

5. Contact Information

Address: Building 4, Kechuang Huigu Park, East Hongshun Road, Huaming High-tech Zone, Dongli District, Tianjin

Zip Code: 300300

Contact: Wang Rongguo

Fixed telephone: 022-24890969

Mobile Phone: 18518677771

E-mail: wangrg@tsinghua-tj.org

Research Institute of Composite Manufacturing and Intelligent Identification