Research Center

-

-

Research Center for Surface/Interfacial Micro/Nano-technology

-

Research Center for Additive Manufacturing Technology and Engineering

-

Research Center for Electromagnetic Strengthing for Tools and Bearings

-

Research Center for Intelligent Security Technology and Equipment

-

Research Center for Applied Biological Technology and Equipment

Lubrication Technology Research Institute

The Institute of Lubrication Technology (hereinafter referred to as "Lubrication Institute") relies on the National Key Laboratory of High-end Equipment Interface Science and Technology of Tsinghua University (formerly the State Key Laboratory of Tribology) and Tianjin High-end Equipment Research Institute of Tsinghua University (referred to as "Tsinghua Tianjin Equipment Institute"). Academician Luo Jianbin is the academic leader and Professor Zhang Chenhui is the team leader. The team members gather in many professional fields such as tribology, machinery, chemistry, chemistry, based on tribology super-slip theory, nano-lubrication mechanism and ultra-fine surface processing mechanism and technology, we are committed to developing green lubrication technologies and products with international advanced level and independent intellectual property rights, such as high lubricity water-based diamond wire cutting fluid, the third and fourth generation advanced semiconductor grinding and polishing fluid, wind power/high-speed rail/new energy vehicle lubricating grease and core function additives, low conductivity coolant, etc, and with the localization of key consumables in the field of high-end manufacturing applications as the main goal, it has been deeply cultivated in the transformation of scientific and technological achievements in colleges and universities, and has achieved gratifying results.

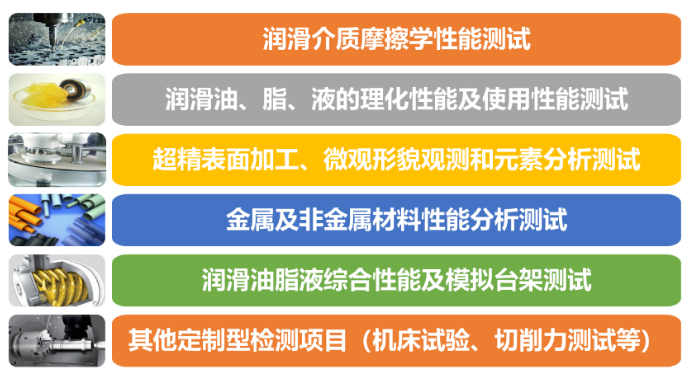

Relying on the equipment platform and technical foundation of the Lubrication Institute, the testing platform of the Lubrication Institute obtained the CNAS qualification certificate in October 2020, and actively carried out external testing business to provide testing services related to tribology, lubricating oil and metal/non-metallic materials for domestic and foreign manufacturing enterprises and university research institutes.

Physical and chemical laboratory Testing laboratory

Polishing laboratory office area

External inspection items of lubrication institute

Core Technology

(1) Water-based diamond wire multi-line cutting fluid formulation technology;

(2) Chemical mechanical polishing formula and process of the third generation semiconductor silicon carbide substrate;

(3) High-efficiency polishing technology and supporting consumables for single crystal/polycrystalline diamond substrates;

(4) Single agent domestic wind power gear oil formulation technology;

(5) low conductivity coolant formulation technology and application process;

(6) Green synthesis technology of anti-friction and anti-wear additives and energy-saving and noise-reducing high-speed rail gear oil blending technology;

(7) low temperature multi-use lubricating oil single agent formulation technology;

(8) Water-based/oil-based drilling fluid extreme pressure anti-wear lubricant synthesis technology.

Technical Field

The technologies involved in lubrication have independent intellectual property rights. Based on the lubrication field, they are committed to the development of green environmental protection, sustainable development and energy-saving and consumption-reducing technologies and products. They have theoretical foregrounding and technological advancement, which can promote the renewal, iteration and technological upgrading of lubrication products in the industry, and help to get rid of the restraint of foreign technologies on China's high-end manufacturing industry. In the difficult period of Sino-US trade war and the United States "neck, it has great economic value and positive social benefits.

Specific industries and areas include:

■ Aerospace;

■ CNC machine tools;

■ Marine engineering equipment and ships;

■ Rail transportation equipment;

■ New energy vehicles;

■ integrated circuits;

■ Agricultural machinery equipment;

■ Electrical equipment;

■ Information technology industry.

Application Case

■ Wind power generation is an important form of wind energy utilization. As of the end of 2022, my country's wind power has a cumulative installed capacity of 0.365 billion kilowatts, but fan-specific lubricating grease products are monopolized by foreign countries and are known as the only link in the industrial chain that is not domestically produced. The team of the Lubrication Institute has developed a single-agent domestic wind power lubricating grease formula product for different fan operating environments such as dry, humid, sandy, high and low temperature. The product performance is equivalent to or even superior to similar foreign products. The price has a competitive advantage over similar foreign products. The product has passed the third-party physical and chemical indexes, application performance and bench test, and has obtained Flanders certification.

■ According to the advance layout of application technologies such as clean energy related equipment, processes and consumables, a low viscosity ETF-4(100oC kinematic viscosity is 4.4 mm2/s) with excellent thermal stability, mechanical protection performance, cooling performance and electrical performance for the high rotation speed (12000rpm) of the motor reducer of the pure electric vehicle transmission system has been developed. The advent of this single-agent domestic oil is more than that of related oil products from well-known lubricating oil enterprises at home and abroad, at least 2 years earlier.

In order to meet the technical requirements of the photovoltaic industry to reduce manufacturing costs and improve product quality, a high-lubricity diamond wire silicon wafer cutting fluid was developed using a water-based fully synthetic formulation system, which can efficiently meet the multi-wire cutting requirements of large-scale, thin-sheet silicon substrate wafers. It has been tried many times in a listed photovoltaic equipment manufacturing enterprise. The TTV and line mark indexes of the cut large-scale silicon substrate are excellent, and there are no problems such as edge chipping, debris and dirt. The qualified rate is higher than that of the current cutting fluid.

■ Committed to the difficulties and requirements in the semiconductor precision processing process, to achieve high speed and high precision dynamic unity, the team self-developed the third generation of silicon carbide substrate CMP polishing fluid, to achieve the final surface roughness Ra<0.1nm. At the same time, the grinding and polishing research of the fourth generation semiconductor single crystal diamond was carried out. By examining the coupling of different physical effects, mechanical effects and chemical effects, a set of mature and stable processing technology was finally formed, and the high-speed and high-precision processing of super-hard and difficult-to-process materials was realized.

With the increasing global attention to energy-saving emissions and the strict requirements of the automotive industry for fuel economy, low viscosity and low sulfur phosphating of lubricants have become the general trend. As an important lubricant additive, extreme pressure anti-wear additive has always been dominated by sulfur and phosphorus. Non-sulfur-phosphorus organomolybdenum extreme pressure anti-wear additive has been paid more and more attention in the lubricating oil industry because of its non-sulfur-phosphorus-free and excellent anti-friction performance. At present, the synthesis technology and products of organic molybdenum, especially non-sulfur-phosphorus-organic molybdenum, are mainly controlled by Vanderbilt Company in the United States. In order to get rid of the control of this technology and the monopoly of this product by foreign enterprises, the team of Lubrication Institute has carried out the green synthesis technology research of non-sulfur-phosphorus-organic molybdenum, and innovatively developed a one-step normal pressure synthesis method with simple synthesis method and high yield, the resulting product has good oil solubility and antifriction properties, certain anti-wear and self-healing properties, and low pungent odor. At present, many models and 10,000 kilometers of driving tests have been carried out. The test results show that the oil additive products with non-sulfur phosphorus organic molybdenum as the core additive can provide 5% ~ 8% fuel saving effect.

Instrument and equipment

Contact Information

Address: Building 4, Kechuang Huigu Park, East Hongshun Road, Huaming High-tech Zone, Dongli District, Tianjin

Contact: Zhou Yue

Zip Code: 3000161

Contact number: 022-84819490

E-mail: zhouy@tsinghua-tj.org

Fax: 022-84819489

Lubrication Technology Research Institute